Pioneering a new class of materials for a circular economy

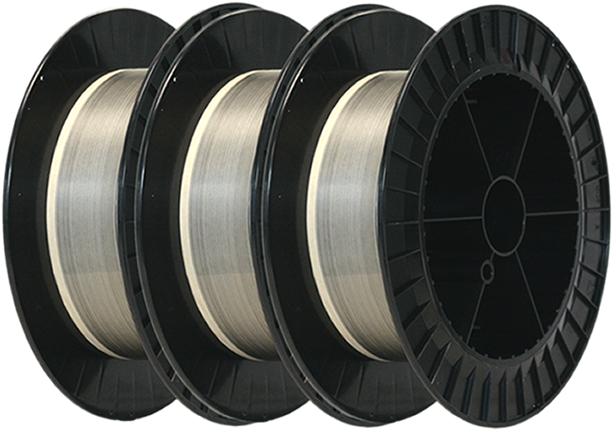

Ceramic Fibre

TISICS manufactures continuous silicon carbide (SiC) mono-filaments at our plant in Farnborough, UK.

The high performance SiC fibre is produced by chemical vapour deposition, in 100µm and 140µm diameter variants.

Our team has been part of Europe's core expertise in SiC mono-filament development since the 1980s, providing an unrivalled

knowledge base, from fundamental technology to finished components.

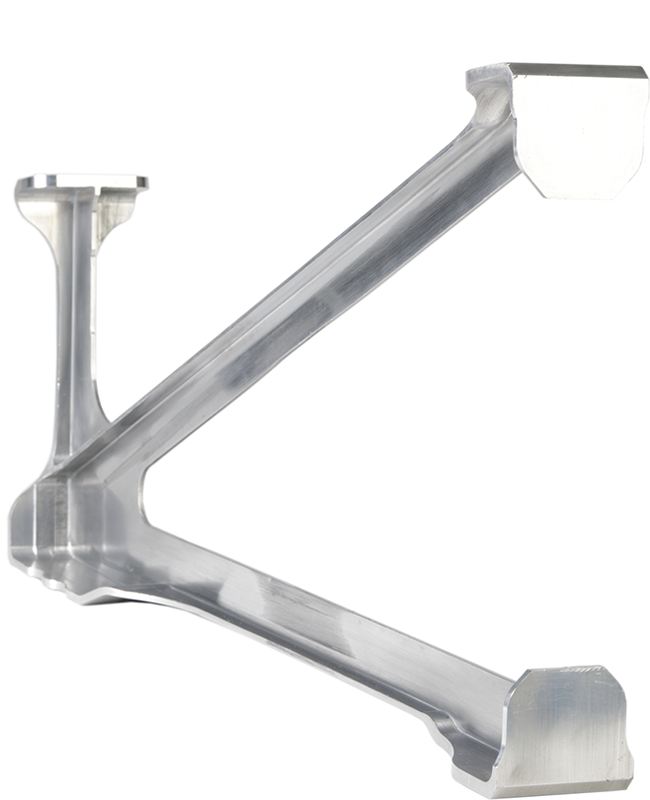

Net-Shape Manufacture

TISICS utilises net-shape, an additive manufacture process to form complex metal shapes with fully bonded joints,

which typically cannot be achieved with conventional manufacturing processes.

TISICS' net-shape fabrication can vastly improve production time, cost, and sustainability by reducing processing time and material waste,

compared with conventional approaches such as forgings and castings. Components achieve full densification, with minimal secondary machining

as required.

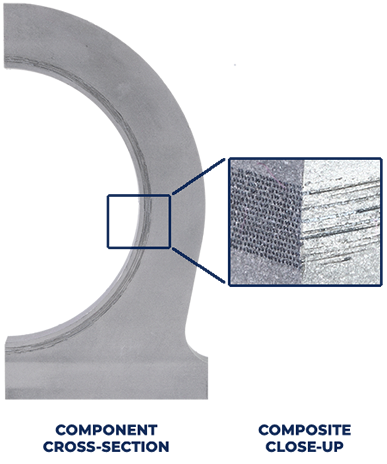

Metal Matrix Composites

TISICS incorporates silicon carbide fibre into a metal matrix to form components. Like all composites, these fibre reinforced

metals benefit from the properties of both the fibre and the matrix. The ceramic fibre provides extremely high strength and

stiffness with little or no variation in performance over the full operating temperature of the component.

Metal composites are designed to provide load transfer through the composite in the final part. TISICS engineers work with

customers to optimise component design and are experienced in delivering fibre architecture derived through finite element modelling.